Specialized in Civil Engineering Design and Temporary Earth Retaining System Urban Space Engineering Co., Ltd.

Home > TAW method > Economic Analysis

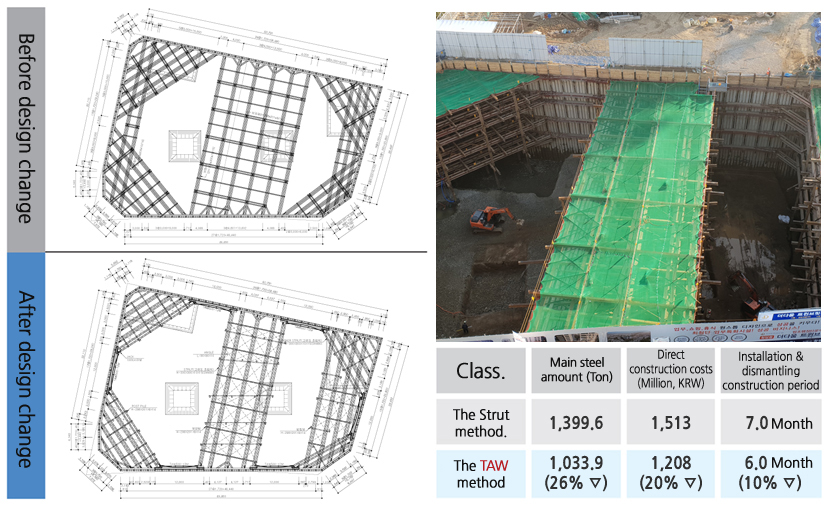

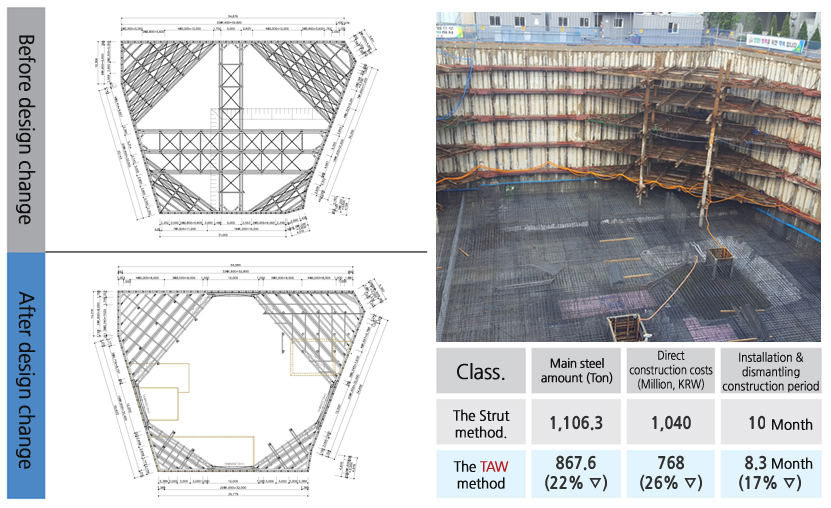

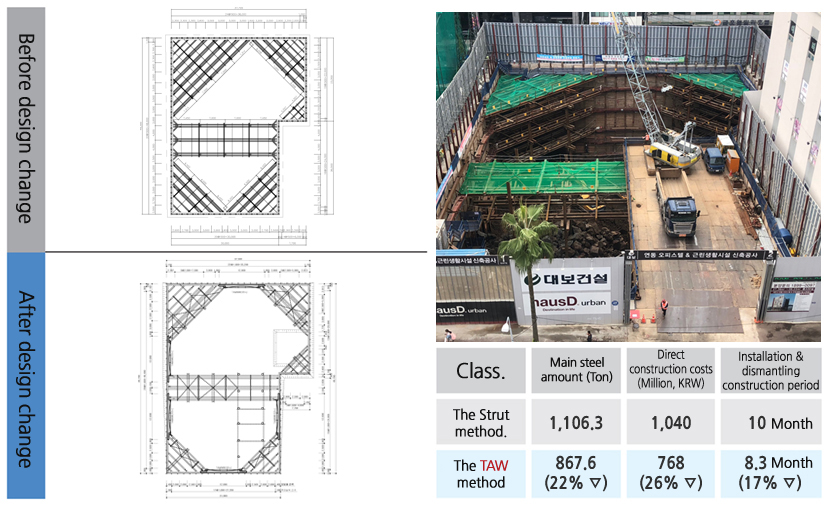

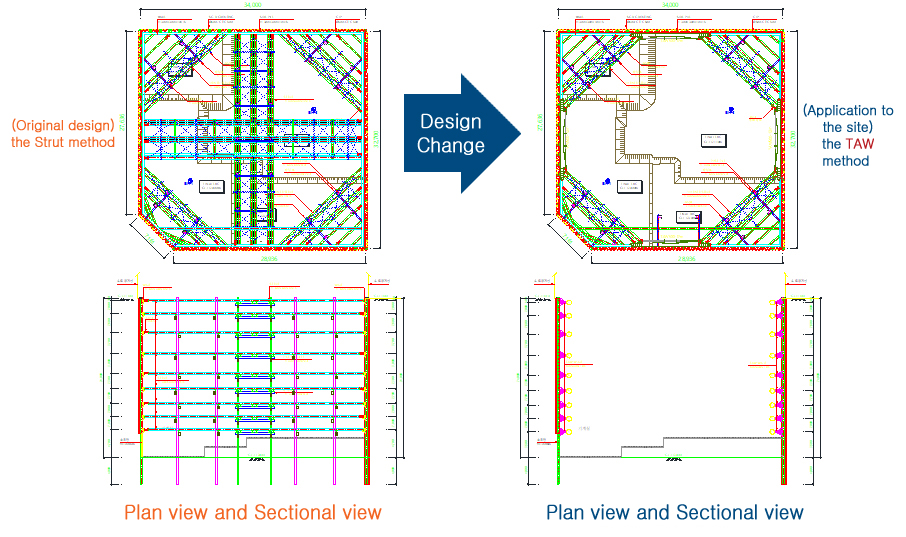

We have a lot of cases of design change to the TAW(Tied Arch Wale) Method with excellent constructability and economic efficiency compared to the Strut method.

The following economic analysis was prepared through the course of review steps of the nationally certified cost-calculating service institution in each site where construction has been completed by changing design from the Strut method to the TAW Method.

Site: MADELEINE Studio Apartment (Riverside in Misa-District)/ Underground Wall CIP D500Maximum earth pressure 274.4kN/m

Site: MADELEINE Studio Apartment (Riverside in Misa-District)/ Underground Wall CIP D500Maximum earth pressure 274.4kN/m

| Class. | the Strut method | the TAW method | Percentage ratio |

|---|---|---|---|

| Installation of piles | 34places | 18places | 52.9% |

| Pile cutting/pullout | 34places | 18places | |

| Installation/removal of casing | 656m | 347m | |

| Pile connection | 68places | 36places | |

| Installation/removal of brackets and steel parts | 482places | 510places | 105.9% |

| Installation of stiffener | 3,024places | 1,584places | 52.4% |

| Installation/removal of piece brackets | 378places | 216places | 57.1% |

| Installation/removal of strut supports | 17places | 10places | 58.8% |

| Manufacturing of struts | 756places | 684places | 90.5% |

| Connection of struts (more than 10m) | 486places | 162places | 33.3% |

| Installation/removal of strut reinforcements | 5,786m | 2,259m | 39.0% |

| Installation/removal of screw jacks | 315places | 207places | 65.7% |

| Steel materials transport in round-trip | 984,581ton | 540,289ton | 54.9% |

| Class. | the Strut method | the TAW method | Percentage ratio |

|---|---|---|---|

| Steel materials for piles | 952m | 504m | 52.9% |

| Rented materials 49.142ton | Rented materials 26.016ton | ||

| Loss materials 13.119ton | Loss materials 6.945ton | ||

| Installation/removal of brackets and steel parts | 9,488ton | 10,058ton | 105.9% |

| Steel materials for wales | 135,698ton | 214,571ton | 158.1% |

| Installation/removal of piece brackets | 13,608ton | 7,776ton | 57.1% |

| Installation/removal of strut supports | 58,978ton | 35,198ton | 59.7% |

| Steel materials for struts | 6,153.3m | 2,688.3m | 43.7% |

| 578,410ton | 252,700ton | ||

| Installation/removal of strut reinforcements | 76,954ton | 30,045ton | 39.0% |

| Installation/removal of screw jacks | 13,545ton | 8,901ton | 65.7% |

| Total steel materials (including loss) | 984,581ton | 540,289ton | 54.9% |

After changing design and constructing to the TAW method, 985 tons of steel materials designed and expected by the Strut Method were reduced to 540 tons saving by roughly 45%.

In addition, the TAW method instead of the Strut Method, roughly 56% of the construction cost expected by the Strut Method was used to complete the construction. Thus, roughly 44% of the construction cost wae saved like reduction ratio of steel materials.

| Class.[Unit: KRW] | Existing similar technology(the Strut method) | The TAW Method | Remark |

|---|---|---|---|

| Material costs | 407,639,324 | 259,325,651 | - |

| 100% | 63.6%(∇36.4%) | ||

| Labor costs | 976,294,686 | 520,222,076 | - |

| 100% | 53.3%(∇46.7%) | ||

| Expenses | 103,934,135 | 68,345,893 | - |

| 100% | 65.8%(∇34.2%) | ||

| Direct construction costs | 1,487,868,145 | 847,893,620 | Total of material costs, labor costs, and expenses |

| 100% | 57.0%(∇43.0%) | ||

| Total of material costs | 2,318,019,991 | 1,295,063,800 | labor costs, and total expenses |

| 100% | 55.9%(∇44.1%) | ||

| Total construction costs | 3,040,972,000 | 1,693,762,000 | - |

| 100% | 55.7%(∇44.3%) |

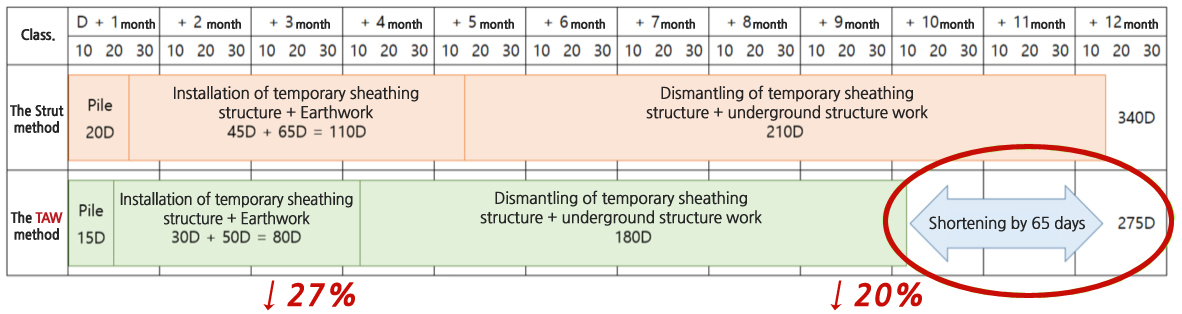

Actual construction period from pile work to underground structure work by the TAW method was 275 days and predicted construction period by the Strut Method was calculated to be a total of 340 days. Therefore, by applying the TAW method, it was analyzed that the construction period was shortened by roughly 20%.

These economic efficiency analysis cases by changing design in sites were analyzed by using the same method as the analysis of the nationally certified cost-calculating service institution

All of these sites were constructed completely after changing a temporary sheathing system from the existing Strut method to the TAW(Tied Arch Wale) method.